Boot Wash Station

SKU

IA3412

The Boot Wash Station is an inexpensive and easy to install unit which helps to keep your site buildings clean and safe. Our innovative design has made it easier than ever to effectively clean site boots and footwear. The in-line version covers usage of up to 3 workers at a time whereas the back to back version covers two men at a time. The BTB is advantageous when space is at a minimum.

As low as £808.75 £970.50

In stock

Quickest Available Delivery: Quickest Available Delivery: 3 Day Delivery

In-Line Boot Wash System

- Width - 710mm

- Height - 1100mm

- Length - 1460mm

- Type - 3-Man

Back-To-Back Boot Wash System

- Width - 710mm

- Height - 1100mm

- Length - 1460mm

- Type - 2-Man

STANDARD FEATURES

- Plumbing Waste System to sump to remove internal waste water.

- Lightweight robust plastic sub-frame.

- Water flow through each brush with individual isolator

- Heavy duty galvanized foot grid.

- Finished in bright orange and silver.

Need any help? Contact HERMEQ Today.

Contact our team via phone 0800 043 2520, email sales@hermeq.com or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

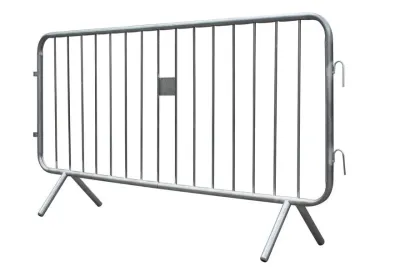

- Height: 2.0 meter

- Width: 3.0 meter

- Weight: 17kg

- Gauge: 1.2mm tubular frame

- Finish: Galvanised to BS EN 10244-2 standard

- Anti-climb mesh infill 250mm x 50.8mm

How many Fence Couplers (Clips) and Rubber Block Fence Feet will I need?

If you are erecting round top mesh fencing panels then as standard people purchase sets, which include one panel